One of the types of fixed orthopedic structures is a stamped-soldered bridge prosthesis. As the name suggests, two technologies are used in the manufacturing process of the product: first, single crowns are created from special metal sleeves by stamping, after which they are soldered together into a single whole. Today, this type of prosthetics is considered obsolete and is practically not used.

Contact numbers of our clinics:

Belarusian (+7

or Leave a request and we will call you back

Leave feedback

Structure

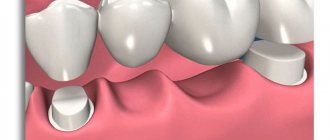

The teeth in an orthodontic bridge are made of metal. The most commonly used are cobalt-chromium alloys. The design of this type of prosthesis implies the presence of at least 2 crowns, which serve as supporting elements.

Stamped-soldered bridges are a type of prosthetics in dentistry.

The design contains at least 2 crowns, between which an artificial tooth is located. Products are classified as chrome plated or titanium nitride coated.

If the patient experiences discomfort after installation, the deficiencies are corrected. High-quality care involves the use of home irrigators.

Between them is an artificial tooth. The prosthesis can be solid or have a lining made of composite materials or plastics (facet or insoma). Structures of the second type have low strength, they require special control and periodic modification.

The reliability of titanium stamped-brazed bridges depends not only on the quality of the laboratory’s work, but also on the health of the patient’s supporting teeth.

Medical titanium does not leave a metallic taste in the mouth and does not oxidize.

Dentist

Novikova Olga Alexandrovna

8 years of experience

The chewing surfaces of dentures should follow the natural pattern of teeth as much as possible to achieve optimal occlusion. The buccal cusps below and the palatal cusps above are especially important. They compress food and are also responsible for distributing the chewing load along the vertical axis of the bone formation.

The buccal tubercles of the prosthesis above and the lingual tubercles below are responsible for separating food, ensuring clear articulation and protecting the surface of the cheeks and tongue. They are called "protective" because of their functions.

Reviews

Dental prosthetics is always associated with some problems, the number and severity of which can be reduced if you carefully approach the selection of material for the product and the technique for its manufacture.

When deciding to restore the completeness of the dentition with soldered dentures, it is important not only to focus on their cost, but also to consider all their pros and cons in the long term.

You can share your experience and impressions about dentures by leaving a comment on this article.

If you find an error, please select a piece of text and press Ctrl+Enter.

Tags fixed dentures

Did you like the article? stay tuned

No comments yet

Kinds

Stamped-soldered dentures differ in the method of making crowns and the type of coating on them. Depending on the spraying material, the structures are:

- Chrome plated - the coating is applied by galvanic means in a special bath. An electric current is applied to the surface of the prosthesis, which attracts the material to itself, creating a chromium oxide film. This coating is highly resistant and inert to liquids, including biological ones. The only condition for maintaining the film is access to oxygen. Without it, if the coating is damaged, corrosion will form (electrochemical, chemical, intercrystalline).

- Coated with MZN (titanium nitride) - in appearance imitates yellow gold. This type of spraying protects the prosthesis from natural abrasion. The coating is unstable - it disappears from the chewing surface of the crown after 6 months; on the outside, the time that titanium nitride remains on the surface depends on the thoroughness of hygienic care. The better you brush your teeth, the faster the coating wears off.

How to treat sore gums under dentures

Soreness and swelling of the gums is a common problem, especially when wearing dentures.

Chrome crowns are more durable, but not as popular due to the color of the plating.

According to the production method there are:

- Crowns stamped using a combined method (MMSI method): maldin or unvulcanized rubber is used as a counter-stamp. D.N. Citrine from MMSI suggested making it from a metal that melts easily.

- The method of internal stamping (production of a crown along a ring): is relevant in case of tooth destruction of significant proportions, if the cast is not informative regarding the relief of the neck.

- Parker method (external stamping): the case is exposed to high temperature, then placed on another die and final stamping is done with a Parker apparatus. It consists of a hollow base and a cylinder that fits into it. Inside the device there is unvulcanized rubber or maldin.

The choice of manufacturing method does not affect the quality of the prosthesis. It is reflected only in the costs and efforts applied to the production of an orthodontic unit.

Production technology

Creating soldered prostheses is a complex and lengthy process. It includes several mandatory clinical and laboratory stages.

Taking impressions

Before taking impressions, a set of primary measures is carried out, the purpose of which is to ensure the functionality of the dentofacial apparatus and its future health.

It includes a comprehensive examination and therapy of the patient’s oral cavity in identifying diseases.

The following actions of the dentist are aimed at directly preparing the teeth for prosthetics. If there are indications, the supporting units are necessarily cured, and if necessary, the nerves are also removed .

After preparing the oral cavity, the supporting teeth are prepared (grinded). This manipulation provides conditions for reliable fixation of the crowns, and consists in removing a certain layer of dentin from the surfaces of these elements.

The preparation must take place under local anesthesia with simultaneous cooling of the treated area. The size of the removed tissue layer is always equal to the thickness of the walls of the artificial crown, which is 0.3 mm.

During the process, the doctor makes sure that the walls undergoing the procedure are parallel.

At the end of all actions, an impression is taken. For this, a standard impression tray and alginate mass are used. Instead of alginate, you can use dental plaster, but due to the labor-intensive nature of the work, it is used in isolated cases.

Important: to improve the retention of the material, it is proposed to treat the edges of the impression tray with adhesive.

After the impression is removed from the oral cavity, it is checked and disinfected. If the patient develops sensitivity and mild pain on the prepared units, the exposed dentin is treated with a desensitizer.

While a permanent prosthesis is being manufactured, the doctor may recommend a temporary one, which will allow the jaws and tissues to get used to the changes. The temporary structure will also protect the treated surfaces from unwanted infection.

In addition, to prevent the occurrence of inflammation in periodontal tissues, regenerative and anti-inflammatory therapy is prescribed.

Model making

The sample is cast in the laboratory by a technician using an impression sent by the dentist.

Modeling the prosthesis body

A roller made of wax fills the space between the artificial teeth. The roller itself is made a little wider and higher than the crowns. While the material is warm, the models are closed to obtain an imprint of the antagonists.

Next, dental elements are modeled from the roller. To do this, first remove excess wax and ensure that the parameters of the roller are identical to the size of the adjacent teeth.

Afterwards, the roller is marked into sections, the number of which is equal to the number of missing units, and each tooth is modeled separately, taking into account the anatomical features of all their surfaces.

To prevent injury to the mucous membrane of the tongue when wearing a prosthesis, do not make a sharp transition between dental units on the oral (lingual) side. On the contrary, this surface is made smooth without sharp boundaries. The cusps of the molars are formed weakly pronounced, slightly rounded.

If the height of the supragingival part, turned towards the site of the defect, is insufficient, a process is retracted from the prosthetic structure to the oral side, which helps to increase the area of contact with the bridge.

Casting

A metal model is cast from a wax sample. All actions are performed in the foundry.

Let's discuss together the features of preparing abutment teeth for a bridge prosthesis.

In this publication we will talk about the advantages of using cad cam technology in dentistry.

Here https://zubovv.ru/protezirovanie/nesemnyie-p/koronki-np/sposobyi-vosstanovleniya.html you will find all the most important things about restoring a damaged tooth crown.

Soldering parts

Artificial crowns for supporting teeth and the intermediate part of the prosthetic structure are fitted to the model. The places where they are soldered are cleaned. The exact relationship of the bridge elements is fixed with wax.

If the prosthesis is long, all its elements are additionally secured with metal wire by gluing it to the lingual surface.

The prosthesis is removed from the model and plastered in a fire-resistant mass. The remaining wax is washed off with a stream of hot water. The soldering areas are lubricated with borax solution. The soldering apparatus is heated up, the soldering areas are sprinkled with borax and solder is applied.

After the solder is evenly distributed over the contact points of the parts being soldered, the heating stops.

The gypsum block is immersed in water for several minutes, and then kept in air until completely cooled.

Finishing

The cast body of the prosthetic product is first adjusted on a sample, and then processed with discs and carborundum stone. The soldering areas are also stone cleaned and polished.

Indications and contraindications

An indication for the installation of dentures of any type is the absence of 2 or more teeth in a patient. Installation of stamped and soldered structures is recommended when the budget is limited and the patient is unpretentious to the appearance of the device.

Why can our articles be trusted?

We make health information clear, accessible and relevant.

- All articles are checked by practicing doctors.

- We take scientific literature and the latest research as a basis.

- We publish detailed articles that answer all questions.

Prostheses of this type have several contraindications:

- pathology ;

- does not have more than 4 incisors, more than a pair of molars, or more than 1 molar;

- bruxism (teeth grinding, mainly at night);

- acute phase of inflammatory diseases of the oral cavity;

- osteomyelitis (melting of bone tissue);

- lack of proper dental care

- severe periodontal disease

In the presence of any of the listed conditions, the installation of stamped and soldered prostheses is not performed.

Contraindications and indications for use

Indications for manufacture and use:

- various damages,

- developmental anomalies of position and shape,

- clasp support arms are incorrectly positioned,

- special support for bridges,

- treatment of tooth abrasion,

- pathological occlusions,

- dysfunction of the masticatory muscles,

- incorrect bite development,

- not large tooth sizes.

Contraindications for use are:

- Defects that disrupt the orientation function of periodontal fibers.

- Defects that are associated with high mobility in the presence of a small clinical crown with a small reserve of periodontal strength. This happens with short roots.

- Diseases associated with viral infection. These are chronic diseases, such as tuberculosis, as well as during periods of chronic exacerbations.

Manufacturing

The devices are made by compressing a sleeve with thin metal walls into a copy of the desired tooth from a hard material. The crowns are connected to each other using soldering, which makes the connection continuous. But the stamping method does not allow the tooth to be recreated with high accuracy, which is why the prosthesis does not fit tightly.

A crown resembles a cap that fits over a tooth, with cusps. The upper part of the dentures should resemble the natural chewing surface as much as possible so that the patient can eat comfortably. But due to low precision during stamping, this is not always achieved.

Installation

The process of installing stamped-soldered prostheses goes through several clinical and laboratory stages.

First stage

The tooth is prepared under local anesthesia. After the procedure, an impression is taken from the remaining bone formations. This occurs on the same day if there is no periodontal damage or at the next appointment if there is any.

The casts are then inspected for damage. If they are not there, they are disinfected and removed. If the prepared teeth cause discomfort to the patient, they are treated with a desensitizer.

The tissues of the oral cavity are treated with anti-inflammatory and regenerating solutions of tincture of oak bark, sage, and chamomile. This will help heal periodontal injuries.

The crowns of the future prosthesis are made using the stamping method.

Second phase

The doctor evaluates the quality of the crowns, especially the density of the marginal fit (in the cervical area), the force of pressure on the periodontium, the correspondence of the contours of the supporting tip with the corresponding part of the tooth, the degree of immersion in the groove (the maximum permissible level is from 0.3 to 0.5 mm), contacts with antagonists (occlusal and proximal).

If parts of the prosthesis do not meet the requirements, they are corrected. During the same visit, the color of the cladding and facets, if any, are determined. With the crowns in place, an impression is taken from the patient. It and parts of the future prosthesis are disinfected and transferred to dental technicians in the laboratory.

Then the remaining part of the prosthesis is manufactured by soldering.

Third stage

The finished orthodontic device is applied to the patient. The physician again examines the structure for occlusal and proximal contacts with antagonists, as well as the flushing zone located under the intermediate part.

Materials for dental prosthetics

In orthopedic dentistry, many different materials are used to make removable and non-removable structures.

If inconsistencies are identified, the deficiencies are corrected. The correct manufacturing and degree of polishing of all structural parts is monitored.

If there are no deficiencies, the prosthesis is fixed in the oral cavity with cement. The procedure is carried out with the jaws closed as much as possible. It is especially important at this stage to ensure that the remaining adhesive materials are thoroughly removed from under the denture and between the teeth.

After completing all stages, the doctor explains to the patient the rules for caring for the orthodontic apparatus.

Bridges

Why are dental bridges needed?

A bridge is a design that is used to replace missing teeth. These are several interconnected crowns that are firmly attached to one base. In two words – this is “dentition”. The main purpose of dental bridges is to replace lost units and restore the functionality and beauty of teeth.

When are dental bridges recommended?

- One or more teeth are missing.

- There are defects or injuries in the oral cavity.

- An old or broken structure needs to be replaced.

Bridges according to manufacturing method.

- Stamped bridge prosthesis. With this method, crowns are created that are fused to each other. In professional slang it is called a soldered bridge prosthesis.

- One-piece bridge prosthesis. It is considered more durable and modern. It is a product made from various alloys. Casting and modeling of the bridge prosthesis also takes place here.

- Adhesive bridge prosthesis. Consists of one crown and fastening elements. Used for the restoration of one tooth.

The method of making prostheses is selected individually for each patient.

Advantages and disadvantages of bridges.

Advantages of bridges:

- Restoration of chewing function.

- Maintaining diction.

- Natural appearance of teeth.

Disadvantages of bridges:

- Grinding of supporting teeth.

- Lack of natural load on bone tissue, which leads to their loss.

- Uneven distribution of functions - neighboring teeth take on the load of the lost tooth unit.

Types of bridges

- Metal bridge prosthesis. Rarely used nowadays. They are too noticeable on the teeth and do not fit well.

- Metal-ceramic bridge prosthesis. Best for replacing molars, that is, teeth that are used for mechanical processing of food.

- Plastic bridge prosthesis. Has many disadvantages. Parts of the bridge may chip and quickly darken.

- Zirconium dioxide prosthesis. Considered durable and reliable. And the most popular due to the quality and durability of the design.

There are also fixed bridges. They differ markedly depending on the material used and the type of installation. Bridge-like fixed dentures differ from removable dentures in their fasteners.

Manufacturing and installation of a temporary prosthesis

The Family Stom clinic produces dentures in its own laboratory using high-quality equipment. The stages of making a bridge are different for each type of prosthesis; this directly depends on the material. To create such structures, we most often use zirconium dioxide. The color of this material perfectly matches the shades of tooth enamel.

Stages of installing a bridge:

1. Diagnostics and panoramic image, 3D modeling of the jaw and future bridge.

2. Preparation of supporting teeth and the entire oral cavity.

3. Making the bridge itself using a cast.

4. Trying on the metal frame and fitting the prosthesis.

5. Installation of the structure itself.

Thanks to the achievements of scientists and doctors in the field of dentistry, the process of installing a bridge has become simpler and painless.

We invite you to our clinic to restore the lost beauty of your natural smile with the help of prosthetics. Our experienced prosthetics specialists will recreate every lost or damaged tooth with 100% accuracy! You will have a guarantee for the quality of Family Stom dental structures - we vouch for the high standard of our work!

Care

Teeth brushing should be done efficiently and daily. After each meal, hygienic treatment of the oral cavity with mouth rinse is necessary. To brush your teeth, it is more convenient to use a special brush made in the shape of a triangle with a recess.

For better oral care, home irrigators are used. Since prosthetics are carried out for a long time, the purchase of this product is justified. It allows you to avoid complications of wearing orthodontic structures (inflammatory periodontal diseases, secondary caries).

total cost

Soldered prostheses are classified into:

- No spraying.

- Coated (crowns look like gold).

- With plastic facet. The most aesthetic option, because The color is close to natural dental tissues.

The final cost will depend on the type of prosthesis and the number of artificial elements in it.

The average price in Moscow is 1500 rubles. for 1 artificial unit, if the prosthesis is with lining, and 1000 rubles, if without a plastic facet.

Advantages and disadvantages

Installation of stamped and soldered prostheses has a number of positive aspects:

- relatively low price;

- extensive experience ;

- reliability.

But, in addition to the advantages, bridges made using this method have a lot of disadvantages:

- fit tightly to the teeth, which increases the risk of secondary caries;

- recede at the gingival margin, which provokes the development of inflammatory periodontal diseases;

- the crown is thin, which is why it wears off quickly when chewing;

- metal can oxidize, giving an unpleasant taste in the mouth;

- unaesthetic .

Stamped-soldered bridges are practically not used in modern medicine, since many analogues have been invented that do not have such significant disadvantages.

General overview

Soldered prostheses are non-removable bridge-like structures, which consist of stamped crowns on supporting teeth and solid-cast spaces soldered to them.

This technology is practically not used today, since soldered dentures, due to a loose fit to the teeth, worsen the general condition of the oral cavity.

As a result, small particles of food and saliva accumulate between the crown itself and the tooth, creating favorable conditions for the active proliferation of infection.

As a result, over a short period of wearing a prosthetic structure, a person develops an unpleasant odor in the mouth, inflammation and many other dental pathologies develop.

Typically, this type of prosthesis is made from the following materials:

- steel alloys with silver cadmium-free solder, chromium, nickel.

- alloys of noble metals - 750 and 900 gold, silver with palladium and cadmium-free gold solder.

Acrylic plastic is used to cover the product.

What are glass-ceramic crowns and the intricacies of manufacturing products.

Come here to take a closer look at the features of Shofu cermets.

At this address we will look at the modern method of digital smile design.