Chief editor of the site:

Snitkovsky Arkady Alexandrovich

Chief physician of the professorial dentistry “22 Century”, dentist, orthopedic dentist

Author of the article:

Scientific team of dentistry “22 Century”

Dentists, candidates and doctors of medical sciences, professors

Nylon removable dentures

The problem of the relationship between oral tissues and the materials from which dentures is one of the main ones in orthopedic dentistry. For prosthetics, various polymer (acrylic, nylon, etc.) and metal compounds are used. Like any artificial element introduced from the outside, they cause numerous complex reactions of the body, the leading of which are adaptive .

It is known that it is removable plate prosthetics that causes the greatest response from the tissues and organs of the oral cavity in the form of a kind of “struggle” with a foreign body. This manifests itself in increased salivation, discomfort for the tongue, impaired diction, etc., which is transitory. Due to the sufficient prevalence of this method (especially in patients of the older age group), the issue of choosing the material and type of construction remains quite relevant to this day.

Is it possible to install a nylon prosthesis for a long time?

Thermoplastic polymers have been used to make denture bases for decades; they occupy a significant share of the dental market. Compared to acrylic materials, they have less rigidity.

The first thermoplastics from Valplast and QuattroTi began to be used in Russian dentistry; for a long period they had no analogues. Today, our dentists use about 20 brands of them to make nylon dentures.

The Russian manufacturer of thermoplastics for dentistry has been with its “Evidsan” for 8 years. Today it is successfully used.

Domestic manufacturers produce new nylon materials: acrylic “Evihard”, “Simplex”, “Belflex” from “Evident Plus”, “Advanced Technologies”, “VladMiVa”, respectively. To assess their quality, you should check the biocompatibility, physical and mechanical properties, and the quality of teeth made from these materials. Studies were carried out on elasticity during bending and tension of 20 materials, which determines their strength. It has been proven that Evidsan is no worse than imported materials, so complete systems can be made from it; their casting shrinkage is low (Gusev V.B. 2021). He notes that Belflex and EvidsanDent nylons have an increased modulus of elasticity.

Russian acrylic "Evihard" is the only representative of these materials. It is distinguished by the high rigidity of the product, which allows it to be polished, is scratch-resistant, and does not form deposits on it when worn. Russian Evihard is superior to well-known brands of imported acrylics. However, more serious experiments are still needed.

In Belgorod, studies were carried out on the accumulation of microbes on the surface of polymers for dental use. A reduced accumulation of them was found on Evidsan; in addition, it is less fragile. Thus, Russian thermoplastics are competitive. This is explained by the fact that raw materials for the production of thermoplastics are imported from abroad, and the cost advantage is obtained as a result of local production.

Thermoplastic dentures are fixed with flexible clasps. The supporting teeth are not ground down. In addition, replacing metal clasps with nylon ones allows them to be used for patients suffering from metal allergies.

Currently, nylon dentures are made from dental thermoplastic, which is soft and flexible.

The popularity of the models is explained by aesthetic indicators. The crowns are attached to a base made of translucent nylon, which transmits light and is completely indistinguishable from the gums. Therefore, the inset structure cannot be distinguished from your own teeth.

Adaptation period and service life

The average duration of getting used to prostheses is 30 days. During this time, the patient learns to eat, talk and smile with new teeth.

However, sometimes the adaptation period can increase to 3 months. This may be due to the following factors:

- atrophy of the alveolar ridge of the jaw (if the patient spent a long time without teeth and their analogues);

- poor stability of the structure (may occur due to smoothing of the gum relief or due to a poorly manufactured prosthesis);

- individual characteristics of the patient’s dental system.

This is interesting: Allergy to dentures - symptoms, diagnosis and treatment, allergy to denture materials

In order to quickly get used to the removable structure, you need to wear it all day. Removing the prosthesis from the oral cavity increases the adaptation time. In addition, the patient should immediately accustom himself to performing all necessary hygienic procedures associated with the operation of the structure in order to avoid discomfort and inflammation.

In the first days of wearing a prosthesis, increased salivation and vomiting may occur. These factors are eliminated on their own, with the body becoming accustomed to the presence of a foreign object in the oral cavity.

When you start wearing a prosthesis, you should gradually increase the load on the masticatory apparatus - chew cut pieces of fruit, bread, and other foods. You should not give up solid food. At first, you should only avoid seeds, nuts and sticky foods (taffy, caramel, etc.).

Setting up the correct articulation also happens quite quickly. If the prosthesis is well fixed, the patient quickly begins to articulate at a normal pace.

To speed up the process, you should practice speaking out loud more and actively use your facial muscles.

Indications for the use of thermoplastic products and contraindications

Dentists recommend the use of flexible systems in the following cases:

- deleting several or one unit;

- allergy to metals;

- cardiovascular diseases, diabetes;

- the client's work involves the risk of facial injury;

- having an allergy to acrylic plastic.

- if there is a high probability of loss of the structure from injury (sports, extreme hobbies leading to mechanical loss);

- preservation of occlusion in children during the period of replacement of milk units with permanent ones.

Thermoplastic bridges have contraindications for use. They cannot be installed if:

- defects of a number of teeth;

- overhanging alveolar ridges, atrophy of their processes;

- the presence of root exposure, gingivitis or periodontitis;

- atrophy of the gums, decrease in their level;

- differences in the level of the gingival margin from the teeth for support;

- the presence of periodontal disease;

- the presence of crowns that prevent the installation of the system.

If there are no supporting teeth, implants can be installed.

Competent care

Despite the high level of hygiene of nylon dentures, they require regular care, just like “living” teeth. After each meal, the denture must be rinsed with running water.

If the patient does not have the opportunity to do this immediately after eating, he should first rinse the mouth thoroughly with water , and then, when possible, remove the denture and rinse it.

To avoid damage when washing the prosthesis, you should perform the procedure over a sink filled with water or a towel folded in several layers.

This is especially true for nylon dentures, which additionally have acrylic elements installed - they can be damaged if they fall on a sink.

In the morning and evening, the denture should be cleaned in the same way as regular teeth, using a specially formulated toothpaste (without abrasive elements) and a soft-bristled brush. Specific tools for care are selected individually, together with the dentist.

At night, the structure is placed in a container with a special cleaning solution, or in an ultrasonic bath. This is necessary for better cleaning of the prosthesis and high-quality service throughout its entire service life.

At least once every six months, the denture should be submitted to a dental laboratory for professional cleaning. There, highly specialized cleaning of microdamages that cannot be eliminated on your own, polishing of the surface and elimination of microdamages takes place.

During these routine cleanings, the patient's gums are also examined and, if necessary, the denture is adjusted. Because Nylon is a plastic material; it can be deformed during wear, so such a procedure is necessary.

How to properly care for soft dentures

Maintaining oral hygiene and proper care of the structure will determine its integrity, color retention, and lack of deformation.

Here are some rules that must be followed when caring for nylon systems:

- After each meal, we recommend removing the bridge and rinsing it with warm boiled water. In hot water it becomes deformed;

- they treat it with a special brush and a special paste that will not damage its structure;

- to combat bactericidal plaque, the system should be immersed in a special solution recommended by the dentist;

- every six months the product is sent to a laboratory where cleaning is carried out;

- The cost of manufacturing nylon tooth substitutes is five times higher than plastic ones and 1.5 times higher than clasp ones.

Flexible bridges are a worthy replacement for the classic versions made of metal and plastic, especially for allergy sufferers. But they cannot withstand serious chewing loads.

Typically, the warranty period for manufactured nylon removable dentures is 12 months. But most clinics provide a guarantee for two to three years, subject to full compliance with the rules for using bridges, as well as regular visits to the dental clinic. It is known from practice that careful use and careful maintenance of the system extend its service life.

In order for removable nylon dentures to last a long time, you must:

- Do not use bleaching products.

- Protect from falling, teeth may be damaged. So, nylon partial bridges are removable, but most dentists advise not to remove them at all. If the patient cannot accept this, then they should be stored in a humid environment.

Considering the listed disadvantages, as well as positive qualities, removable dentures made of nylon are considered by practitioners and science as a temporary measure. Long-term use is acceptable if 1-2 butterfly units are replaced. But still, nylon is not yet a worthy replacement for the classics. We are talking about clasp and acrylic prosthetics.

The current high price of a nylon product can only be justified by advertising by manufacturers and its relative novelty in Russia. The contradiction of the nylon system is that its distinctive qualities - flexibility and elasticity - are simply unsuitable for long-term use.

Professional dental care and treatment in Moscow - including calling a dentist to your home, pediatric dentistry, providing assistance to people with disabilities.

Healthy and beautiful teeth are everyone’s dream. The Alexandria Dental Center will help make this dream come true.

Sources:

- https://www.vash-dentist.ru/protezirovanie/semnyie-p/neylonovyie/unikalnyie-svoystva-vertex.html

- https://superdentos.ru/cat/protesirovanie_zubov/protezirovanie_zubov_sjemnoe/termoplastichnye_zubnye_protezy

- https://dentoclass.ru/stati/semnye-protezy-vidy-osobennosti-preimushhestva/

- https://zubovv.ru/protezirovanie/semnyie-p/iz-materiala-vertex-komfort.html

- https://asteralab.ru/services/termoplasticheskie-semnye-protezy/

- https://alexandriadent.ru/ortopediya/nejlonovye-protezy/

Installation of a structure in the absence of teeth

Patients often turn to dentists asking for nylon jaws to be made in cases of complete edentia. This cannot be said about the impossibility of installing such a system. But the client must understand that implementing such a design will require a lot of time, as well as money, because implants will have to be implanted to secure it.

Softness is an excellent quality for performing the basis of a system, but this only applies to partial replacement of a row. With complete edentia, discomfort from the flexible structure will begin to appear immediately when talking and chewing food.

If bridges made of plastic take on 50% of the load, then a nylon dental prosthesis redirects it to the gums. As a result, bleeding wounds form on them.

The bridge is usually attached to the teeth. In their absence, the structure is fixed with glue, which leads to patient discomfort. There is a concern that it could fall out at any time. The increased load on the jaw bones provokes their subsidence - their height decreases by one mm every year. As a result, it becomes unusable and will need to be replaced.

Therefore, dentists, in cases of complete edentia, recommend rigid structures.

Possible breakdowns

Damage to the integrity of Vertex products is quite rare, however, dentists identify the following situations in which product repair may be required:

- chipping or loss of an artificial tooth is eliminated in a dental laboratory by installing a new element of the row;

- if the product adheres poorly to soft tissues, adjustment of the base may be required;

- Elimination of a broken lock is carried out by replacing it with a new one;

- When cracks or breaks in the base appear, it is repaired or a new structure is made.

Dentists pay attention that repairs should only be carried out by specialized specialists. Independent actions can cause even more damage to the structure.

Favorable properties of thermoplastic dentures

- The flexible material facilitates adaptation to artificial products in a few days without experiencing much discomfort. The design has sufficient strength in small areas, and its flexibility prevents chipping.

- Nylon does not absorb liquids, so the structure of the product is not disturbed.

- This material has another important positive quality - it is hypoallergenic. Acrylic and metal clasps cause a rejection reaction (itching, foreign taste, burning) in some patients. Nylon suits almost everyone.

- The low weight of the structure makes life easier. The bridge is well fixed and has increased strength.

- For clients with an increased gag reflex, models without the palate are performed.

- Only from nylon can thin and rigid products be made with injection molded clasps that do not damage the enamel of the support.

Comparison of nylon with acrylic

For the manufacture of dentures in dental practice, two types of material are most often used - nylon and acrylic.

Each of these substances has both advantages and disadvantages, which affect the convenience and duration of use of the structure.

| Features of nylon products | Features of acrylic systems |

| High density of adhesion to soft tissues due to elasticity and flexibility. | The hardness of the material often results in an insufficiently tight fit to the gums, as well as their rubbing. |

| Non-toxicity of the product. | Release of toxins with prolonged use. |

| No allergic reactions to the material. | The likelihood of developing allergies. |

| Possibility of deformation as a result of exposure to high temperatures and chewing loads. | Maintains shape throughout the entire period of operation. |

| Inability to use glue to increase the degree of fixation | Possibility of using adhesives to enhance fixation in the oral cavity. |

| Non-porous structure, thanks to which the product does not stain, does not absorb foreign odors and is not prone to plaque accumulation. | The high porosity of the material over time leads to discoloration and the accumulation of bacterial plaque. |

| High price | Affordable price |

Negative qualities

- Compared to clasp and plastic structures, making a product from nylon is more expensive.

- The system requires special care - it can be damaged with a regular toothbrush, leaving scratches on the surface. Odors and moisture penetrate through them. Stable spots appear, provoking the development of inflammatory processes.

- Due to the softness of the material, the product becomes mobile when used. It does not tolerate pressure, transferring it to the gums, which atrophy - the jaw “sags”. Reducing its height by two mm makes the system unusable - it must be periodically replaced. If you ignore the timing of replacement, the hooks injure the mucous membrane.

- The flexibility of the material causes pain when chewing, since the load is distributed unevenly and the denture is deformed. This occurs in structures installed in the absence of a large number of units. Due to the deformation, it has to be corrected several times. In the event of a breakdown, the system cannot be repaired and will need to be re-installed.

- Products made of nylon cannot be sanded in places of contact with the surface of the gums. Plaque accumulates there, causing a disgusting odor. To prevent this from happening, you should follow your dentist's instructions for caring for the bridge.

- A flexible prosthesis is not wear-resistant; if handled carefully, it will last 2-3 years.

- It is difficult to chew food - the structure “moves apart”.

- Acrylic teeth do not fit well with the base, and they are lost due to malocclusion. Deposits appear between them.

- The product cannot be repaired.

- After correction it is not polished.

- After 6 months of wear, roughness appears.

- You will have to give up hot food, alcohol-containing drinks more than 40%, coloring products: coffee, beets, tea, smoking.

- If you are allergic to acrylic, you should select the material individually.

Some of the negative properties are noted by dentist Mova A.V. In his dissertation, Ph.D. Kovalenko, O.I., when studying the Valplast basis, mentions aesthetics, quality of life using nylon bridges only for 12 months of use. Subsequently, all studied parameters deteriorate. The presence of microbial deposits of periodontopathogenic microflora was assessed, which revealed that thermoplastic is inferior to absolutely all similar materials - this limits its use. However, a substitute that covers 1-2 units does not bring any inconvenience. Dental nylon removable dentures made from it can only be used as a temporary measure. Adaptation of clients to removable systems is really fast, but after a year the appearance changes and microbial plaque is poorly removed.

Features of the material

Vertex Thermosens is a semi-rigid thermoplastic material that is available in the form of granules in a variety of color shades, which allows the device to be manufactured to ensure maximum resemblance to the patient’s oral tissue.

Experts in the field of prosthetics point to the following characteristics of the material, which distinguish it favorably from other plastics during use:

- high speed and ease of polishing;

- low degree of shrinkage of the material, ensuring precise fit of the finished product in the patient’s oral cavity;

- strength, allowing you to abandon the use of metal components;

- simplicity in choosing colors due to the presence of 12 shades of substance granules;

- translucency and light reflectivity, allowing to minimize the visibility of the structure in the patient’s oral cavity;

- Possibility of relining and pressing the product.

Patients of dental clinics who have had products made from Vertex Thermosens polyamide installed also mention its many advantages:

- high strength , promoting uniform distribution of the chewing load, and eliminating cracking and deformation of the product under the influence of high temperatures and mechanical stress;

- hypoallergenic due to the absence of monomers , chemical additives and toxic substances;

- high-quality color rendition of the finished product and the absence of coloring during use;

- low porosity , guaranteeing the absence of absorption of foreign odors;

- lightness of design due to the absence of metal parts.

Flexible and comfortable prosthesis: myth or reality?

Plastic dentures will allow you to forget forever about the discomfort that is typical when using rigid structures. By installing them, the patient receives the following benefits:

- natural shape of the dentition;

- natural tooth color;

- the presence of fissure-tubercle contact between artificial teeth and antagonist teeth;

- excellent fixation;

- high aesthetics and reliability.

To make thermoplastic dentures, a special type of plastic is used, which is produced using a unique technology. The main feature of this material is that it transforms into a highly elastic state when heated to a certain temperature. Thermoplastic prostheses have the following properties:

- high elasticity and strength;

- precise fit and secure fixation;

- lightness and lack of chafing;

- aesthetic appearance and natural appearance of clasps.

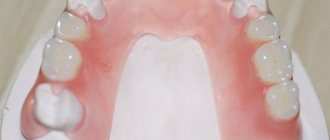

Appearance of a prosthesis made of thermoplastic materials

When is the use of thermoplastics justified?

Thermoplastic plates are a solution for those patients whose teeth cannot be ground and there are minor defects in the dentition. Due to the unique lightness and softness of the structures, thermoplastic dentures can be used even in patients with inflammation of the periodontal tissues.

In addition, this denture material does not cause tissue irritation (which is typical for acrylic structures), and prevents the development of inflammatory processes in the oral cavity, which often occur during the use of plastic structures.

This type of prosthesis does not require special care. To ensure long service life and maintain the aesthetic appearance of prostheses, you should use products such as Corega, Ultra Sonic Wallplast or ValClean. You can also use dental floss and regular soap. Every six months you should undergo a professional cleaning procedure.

Our prices

| Code no. | Name of procedures | Unit of measurement | Cost, rub. |

| 753 | Partial elastic monomer-free prosthesis “Quadrotti” | 55 000,00 | |

| 754 | Complete removable monomer-free prosthesis “Quadrotti” | 65 000,00 | |

| 762 | Clasp prosthesis (up to 2 clasps) | 45 000,00 | |

| 763 | Clasp prosthesis complex (more than 3 clasps) | 55 000,00 | |

| 764 | Clasp prosthesis splinting | 85 000,00 |

* The prices indicated on the website are not a public offer. The exact cost of treatment can only be determined at an appointment with a doctor.

Prices for treatment in Korolev full price list

Share on social media networks:

Article Expert:

Konoplya Larisa Mikhailovna

Orthopedic dentist - general practitioner. Education: Minsk State Medical Institute. Regularly improves his professional level at international seminars and conferences.

Work experience 30 years

About the manufacturer

The Israeli dental company Perflex LTD specializes in the production of thermoplastic polymers for the manufacture of dentures. Its product range also includes instruments, components and materials for dental laboratories.

The company was founded in 2007. This was preceded by a long period of research, development and improvement of thermoplastic materials used in dental prosthetics.

Perflex materials are used in 129 countries around the world. The company's representative office in Russia (Perflex RUS) with an office in St. Petersburg was opened in February 2013. All Perflex LTD products comply with international standards.

We recommend that you read

Prosthetics on implants

Dental prosthetics

Zirconium dentures

Fixed dental prosthetics

How else to care for dentures?

In addition to the standard cleaning procedure, dentures require additional care. It is necessary to use a special disinfectant, which is easy to find in a regular pharmacy (they come in different forms). They need to be dissolved in water, and then the prosthesis is lowered into it. 30 minutes is enough for disinfection.

No matter how high-quality your prosthesis is, you should avoid any contact with aggressive chemicals. It is also necessary to exclude any mechanical impact (cleaning is best done over a soft towel to prevent breakage in the event of a fall). If you find any crack or small chip, you should immediately contact a specialist without making any attempts to repair anything.

Reviews

Dentists usually do not inform patients from what materials the elements of their prosthesis are made. And this is understandable, in order to receive a quality service, there is no need to be informed in all its intricacies.

If you do know that your prosthesis was made from Pereflex thermoplastics, tell us how high quality and comfortable it was. Comments can be left at the bottom of the page.

If you find an error, please select a piece of text and press Ctrl+Enter.

Tags dentures removable dentures

Did you like the article? stay tuned

Previous article

Alvostaz sponge - hemostatic and antiseptic compress

Next article

Which dentures are considered best: removable or fixed?